drive shaft coupling failure

Squeaking sounds are one of the first signs that appear. 1 the friction caused by the shaft interference fit and 2 via the surface of the key.

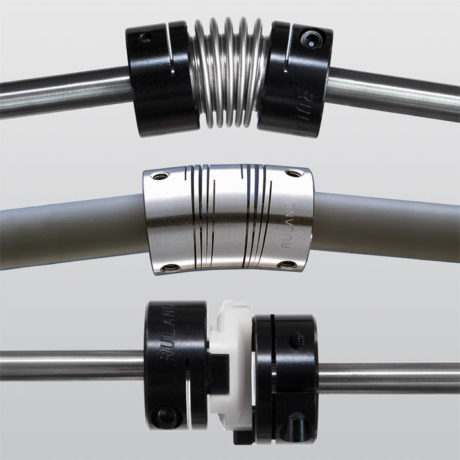

Flexible Shaft Couplings For High Temperature Applications

Misalignment can be caused by improper installation of the pump and motor pipe strain even bent shafts.

. Up to 50 of damage to rotating equipment is directly related to misalignment. This yoke slides inward and outward of the transfer case to deliver the power. All flexible shaft couplings are designed to allow for misalignment of one.

They are typically simple to install and maintain. Noise at the coupling Powdered rubber particles or leaking lubricant directly below the coupling depending upon coupling type Process fluid andor oil leaks at the drive driven or both shafts Premature shaft shaft keyway or key fatigue. Most coupling manufacturers will even assist engineers.

The shaft and bore wear and fret causing premature repair or failure. If the shaft is to be removed the gearbox oil will need to be drained first. It can also cause complete failure of the other.

This is one of the most common causes of a coupling failure. To do this the screw material must be harder than the shaft material. A shaft coupling is an extremely efficient method of power transmission.

For this application the coupling hubs having interference fit bores torque is transmitted between the shaft and coupling hub through two methods. At Crane Engineering we find the root cause of coupling failure ladders up to one of the following reasons. The shaft couplings will also need to be undone for the same reason.

Their holding power is derived from the screw biting into the shaft. Drive shaft coupling failure. These sounds mean that you need drive shaft.

If the cushioned plate option is followed this is not necessary. When selecting the coupling thoroughly review the peak power the pump will experience during abnormal conditions ie start-up shutdown upsets frequent startstops etc. Symptoms of misalignment include the following.

There are only four basic failure mechanisms. If your shaft is hardened typically Rockwell C. Misaligned pump or motor shafts lead to damage or breakage of the couplings.

The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench. In fact several studies state that misalignment is the reason for nearly 70 80 of pumps failing. Symptoms Of A Broken Drive Shaft Squeaking Sounds.

Many need little maintenance at all beyond installation other than an occasional inspection. A shaft coupling is an extremely efficient method of power transmission. Installation Human Errors Thermal Growth Worn Bearings Dynamic Twist of Skid Settling Bases Foundations Pipe strain.

The slip yoke directly connects with the drive shaft via a universal joint. The primary purpose of couplings is to join two pieces of rotating equipment while. It is a major component of the drive shaft and coupling shaft linked with the housing on the center bearings.

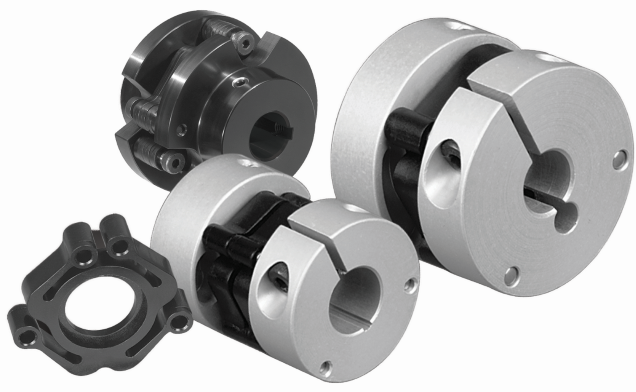

Excessive misalignment between joined shafts is one of the most common reasons for coupling failure due to the creation of loads that surpass the coupling specifications. Sizing the coupling for peak motor starting torques in addition to considering the inertias of the pump rotors or the drive train of piston pumps could avert a failure. Vibrations are another symptom of a failing driveshaft that requires drive shaft repair.

If the cushioned plate option is followed this is not necessary. Worn out u-joints couplers or carrier bearings can cause the driveshaft to vibrate. Using Control-Flex flexible shaft couplings on your encoder will guarantee accuracy and.

Most coupling manufacturers will even assist engineers. A few of the most common include. When the surface of the keyway is damaged the key no longer has proper contact and the shaft hub.

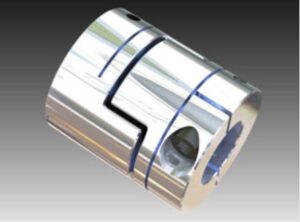

Drive Shaft Coupling Failure - To avoid premature coupling failure it is critically important in design selection to match the correct coupling to the misalignment condition or combination of conditions present. Most are also tolerant of slight misalignment temperature extremes humidity loads and so on. These zero backlash flexible shaft couplings are engineered to ensure accuracy and feature clamp hubs for a superior secure and vibration-resistant shaft connection.

This is a common issue with set screw shaft collars. The flex elements offer ultralow bearing reaction loads caused by shaft misalignments. 7 Tube Yoke and Slip Yoke.

Zero Backlash Flexible Shaft Couplings Shaft Couplings

180 Land Rovers Being Recalled For Possible Driveshaft Coupling Failure Truck Trend News Range Rover Classic Land Rover Range Rover

Shaft Coupling Definition Types Uses Working Principle Advantages Complete Guide Engineering Learn

How To Avoid Coupling Failures Fastener Engineering

12 Reasons For Coupling Failure And How To Avoid Them Insight Acorn Industrial Services Ltd

Control Flex Shaft Couplings Flexible Shaft Couplings

Eight Best Ways To Wreck Your Coupling Driven System Power Transmission World

Causes For Pump Coupling Failures How To Avoid Them Sintech Pumps

Disc Coupling Finned Coupling All Industrial Manufacturers

Damaged Rubber Part Of Flexible Coupling Installed Between Main Engine Download Scientific Diagram

Flexible Shaft Couplings For High Temperature Applications

Rotex Torsionally Flexible Jaw Couplings Shaft Coupling Ktr

What Is Coupling Definition Types And Uses Engineering Choice